Loading... Please wait...

Loading... Please wait...12V VR6 Water Pump Replacement

Please give credit where credit is due! This DIY was completed ENTIRELY by the hardest working VW Vortex moderator on the site!! Gary Thompson, Ph.D. - vortex ID VGRT6, email address vgrt6@yahoo.com. Please make sure to say thanks to Gary, and if you ever see him at a bar, buy em a beer. These DIY's are more complete than anything Bentley has ever written!!

REPLACING THE MAIN WATER PUMP ON A MKIV 12v VR6

The following outlines the procedure for replacing the main water pump on a MKIV 12v VR6 engine. It is common on high-mileage VR6 engines for the bearing in the pump to fail, resulting in a loud grinding/scratching noise when the engine is running and eventually, a significant coolant leak (the bearing acts as a seal in the pump). Contrary to what the Bentley Manual says, the engine must be raised slightly to replace the pump (it actually neglects to mention anything about having to raise the engine ). The steps below will describe how to prep the engine for raising, how to raise the engine and how to remove/replace the water pump.

The procedure below was based on a '99.5 MKIV Jetta GLS 12v VR6 and should be valid for all MKIV 12v VR6 cars regardless of model and year. The steps for raising the engine to access the water pump will be slightly different on other 12v VR6 cars (MKIII, Corrado, custom swaps), however the steps for actually removing and replacing the water pump should be the same. The procedure may also differ slightly on the MKIV 24v VR6 engine, although the steps below should also be very helpful for replacing the main water pump on that engine.

Please do these procedures at your own risk and be ready to make small adjustments while doing them. Also, please be observant while removing parts so that they go back together correctly.

The procedure below is fairly involved and potentially dangerous and extreme care should be taken while performing it. Depending on how mechanically inclined you are, it should take somewhere between 2 and 4 hours to perform. We had little idea about what to do when we started this procedure (other than researching the procedure for a MKIII 12v VR6) and it took us 4.5 hours to perform, including a lunch and beer break.

I purchased a replacement water pump (VW# 021-121-004-A) at Impex for $48.50 (recently raised to $56). The unit is manufactured by Hepu, has a metal impeller (significantly better than the plastic impeller which is used on some versions of the water pump) and comes with a new o-ring. There is also a Graf version available for roughly the same price. I'm not sure what material the impeller is made of on the Graf unit. Just in case my water pump pulley was damaged from running the engine with a water pump with a bad bearing, I purchased a new pulley (VW# 021-121-031-A) from Impex for $12. I reused the existing bolts when I performed the below procedure. If you want to purchase new bolts (not a bad idea since they sometimes strip when being removed), the VW part#s are N-905-442-01 for the pulley bolts (need 3) and N-902-218-03 for the pump mounting bolts (also need 3). They can be purchased at Impex for $0.62 and $0.95 each, respectively.

For those who want to replace engine/tranny mount bolts that are removed (some are stretch bolts), the part#s are as follows:

- passenger's side engine mount-to-body bolts - VW# N-905-969-02 (need 2)

- pendulum mount-to-tranny bolt, front - VW# N-102-466-03 (need 1)

- pendulum mount-to-tranny bolt, rear - VW# N-905-970-01 (need 1)

- driver's side mount-to-tranny bolts - VW# N-102-096-03 (need 2)

The tools/parts needed to perform the procedures are:

1) two jacks (can probably be done with one, but is easier with two - the procedure in this DIY assumes two jacks will be used)

2) two pieces of wood - I recommend a one foot long piece of 2x6 (only one piece of wood is needed if only one jack is used)

3) small flathead screwdriver (to help undo hose clips and harness connectors)

4) large flathead screwdriver or small pry bar

5) T25 and T30 Torx sockets or drivers

6) medium Phillips screwdriver

7) socket wrench with 10mm, 13mm, 16mm and 18mm sockets

8) 6mm hex socket or wrench

9) long socket extension - 6" or so is fine

10) M8x**x1.25 pitch bolt, where ** is the length in mm (available at Home Depot, Lowe's or other hardware stores). I have not specified a length since it varies depending on the model-year car you have.

Special thanks go to Eric (BCDS2003T), James (James 93SLC) and Shashi (DJ-SBK) for their help with the procedure.

INTRODUCTION

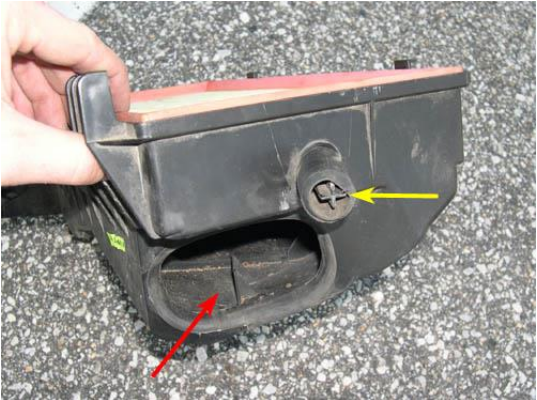

1. The main water pump is located on the passenger's side of the engine, as indicated by the yellow arrow in the picture below.

2. The main water pump is driven by the serpentine belt and is located just below and to the rear of the serpentine belt tensioner pulley. The water pump pulley is indicated by the yellow arrow in the picture below. Unfortunately, the pump sits just to the driver's side of the frame support for the passenger's side engine mount (support is indicated by the red arrow in the picture below - Note: the picture below was taken with the engine already raised, so the access to the pump/pulley bolts is even less than shown). While the pump is approximately 4.15" in length, there is only approximately 1.5" of space between the pump pulley and the frame support. Therefore, in order to get the pump out of the block, the engine needs to be raised nearly 2" and pushed towards the driver's side of the engine bay, and the pump pulley needs to be removed. Raising the engine requires that the passenger's side engine mount and the tranny pendulum mount be disconnected and that the driver's side tranny mount be loosened. It also requires that some items attached to the engine and mounts be removed or temporarily moved out of the way. These steps will be covered in detail in the next sections.

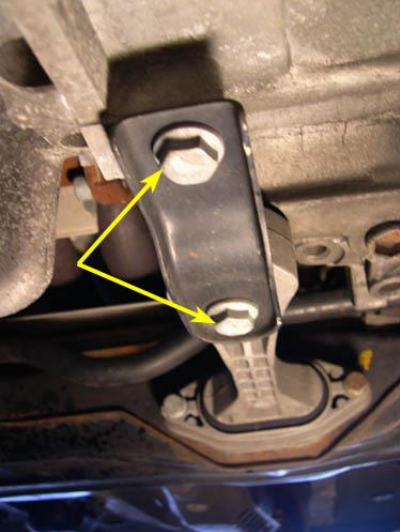

PREPPING THE ENGINE SO THAT IT CAN BE RAISED

3. The replacement of the water pump can be done with the car on the ground or up on ramps or jack stands as you don't need much access to the bottom of the car. That being said, I recommend that you raise the front end of the car to do the procedure. This will allow you to check the engine and exhaust (especially oxygen sensors) as they're being raised to make sure that no binding occurs. Raising the car also provides extra clearance below the oilpan and tranny so that a nice big block of wood can be used between these items and a jack when raising up the engine.

4. Remove the long cover piece on the passenger's side of the engine. To do this, remove the two T30 Torx screws (indicated by the yellow arrows in the picture below) and carefully pull upward on the cover piece.

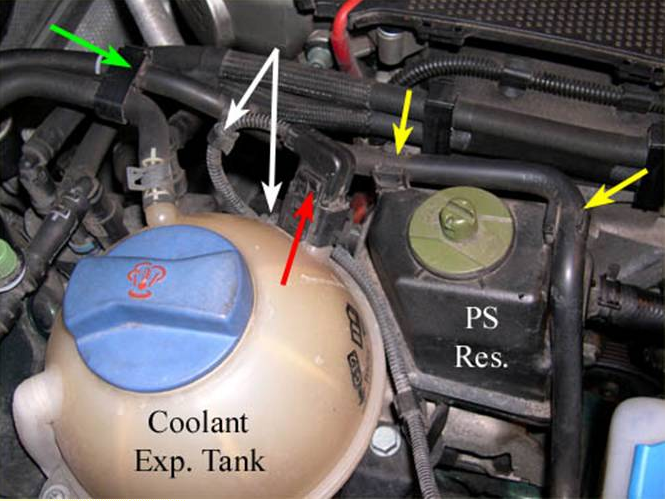

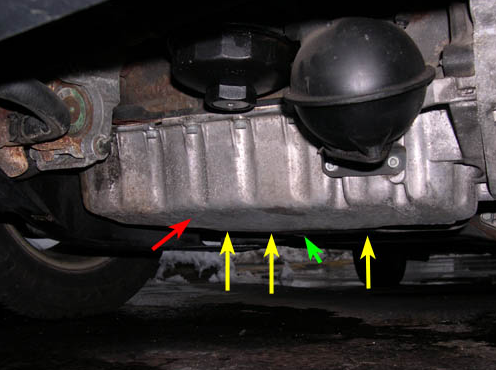

5. The power steering reservoir (PSR - black tank with green cap in picture below) sits directly on top of the passenger's side engine mount and needs to be able to move up freely when the engine is raised. In addition, the coolant expansion tank (CET - white ball with blue cap in picture below) blocks access to the rear engine mount bolt and needs to be moved out of the way. First, unclip the coolant hose from the top of the PSR (yellow arrows in picture below) and then unclip the same coolant hose from the upper CET hose (green arrow in picture below). Next, disconnect the harness connector for the coolant level sensor on the CET (red arrow in picture below). Finally, unclip the sensor leads from the CET and coolant hose (white arrows in picture below).

6. Disconnect the CET from the body by removing the two Phillips head screws indicated by the yellow arrows in the picture below.

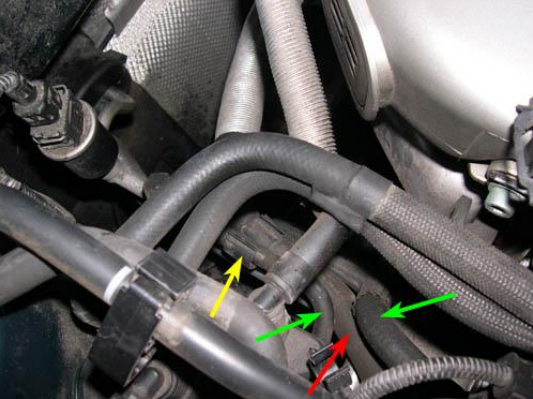

7. In order to move the CET out of the way enough to gain access to the rear engine mount bolt, you may need to unclip (yellow arrow in picture below) the lower CET hose (red arrow in picture below) and move it out from between the two hoses on either side (green arrows in picture below).

8. Remove the 13mm bolt that connects the PSR support to the body, as indicated by the yellow arrow in the picture below.

9. The yellow arrow in the picture below points to a metal coolant pipe (from the secondary radiator) that sits just below and to the front of the upper intake manifold. This pipe needs to be disconnected or it will hit the low pressure service valve of the A/C system (red arrow in picture below) when the engine is raised. The pipe is attached to the manifold by two 6mm hex bolts, one of which is indicated by the green arrow in the picture below. Remove this bolt. The other bolt used to secure this pipe will be removed in step 14.

10. Remove the small engine cover piece with the VW logo on it by removing the single T30 Torx screw (red arrow in the picture below) and unclipping the three spark plug wires from their respective channels (yellow arrows in picture below).

11. Remove the trim piece in front of the battery box by removing the two Phillips head screws indicated by the yellow arrows in the picture below and sliding the piece upwards.

12. Disconnect the hood release bowden cable (yellow arrow in the picture below) from the trim piece just to the passenger's side of the one just removed.

13. Remove the trim piece by removing the two Phillips head screws indicated by the yellow arrows in the picture below and sliding the piece toward the rear of the car and up and out.

14. The second 6mm hex bolt that secures the metal coolant pipe to the manifold is just to the driver's side of the first intake runner, as indicated by the yellow arrow in the picture. It's a very tight fit, but it's possible to get a short hex wrench (shown) in between the manifold and front end to remove the bolt. This step may require some hand contorting and a bit of time.

15. Move the metal coolant pipe (yellow arrow in picture below) towards the front of the car and down along side the hard, flexible hose (red arrow in picture below - part of the secondary air injection system?). This will prevent the hose, which will raise up with the engine, from pushing the coolant pipe against the A/C service valve discussed in step 9.

16. Remove the lower sound absorber panel from underneath the engine/tranny (red arrow in picture below) by removing the four T25 Torx screws that attach it to the car. There are two screws on each side of the panel. The two on the passenger's side of the panel are indicated by the yellow arrows in the picture below.

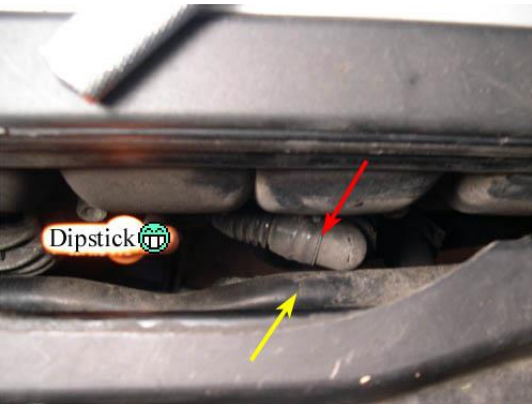

17. When you finally remove the water pump from the engine (we're getting there, I promise ), some coolant will spill out of the block. If you want to prevent this, you can remove the upper oil cooler hose to drain the block. Unfortunately, the upper coolant hose is very difficult to reach, so I just let the coolant in the block (hard to guess how much, but I say around 2 quarts or so) spill out onto the ground. Since my coolant was original (had 145k miles on it), I decided to drain the existing coolant from the radiator and put all new coolant in when the pump replacement was done. (Note that there will still be coolant present in the heater core. You may want to consider flushing out the heater core if you're replacing your coolant, especially if you're switching formulations, e.g. G11 to G12.) It is not necessary to drain the coolant from the radiator when replacing the water pump. An option is to just let the little bit of coolant spill out of the block when removing the pump and then top off the coolant when the new pump is in. The choice is yours.

18. To drain the coolant from the radiator, turn the knob indicated by the yellow arrow in the picture below (on the lower driver's side of the radiator) approximately 45° and pull out. The coolant will come out of the drain marked by the red arrow. Unfortunately, the drain sits directly above the driver's side splash guard (the one being moved aside in the picture) and as a result, the coolant will hit this piece when it comes out and make a mess. I recommend placing a tube on the end of the drain to direct the coolant into a bucket or other large container.

19. The driver's side tranny mount sits directly below the intake air filter box. The air filter box, which is located at the rear driver's side of the engine bay, must be temporarily moved out of the way to gain access to the tranny mount.

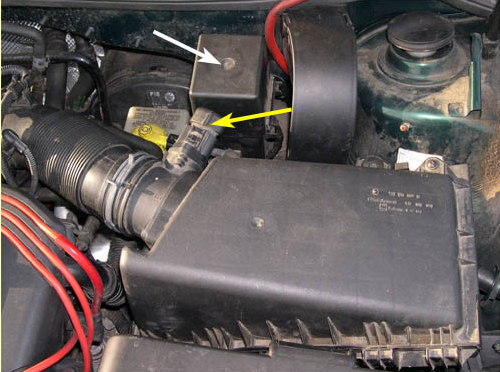

20. Disconnect the harness connector from the MAF sensor, as indicated by the yellow arrow in the picture below. On early model-year MKIV cars, you may need to remove the relay box cover (indicated by the white arrow in the picture below) to be able to do this. On later model-year MKIV cars, there is a depression in the cover which allows the connector to be removed without removing the cover.

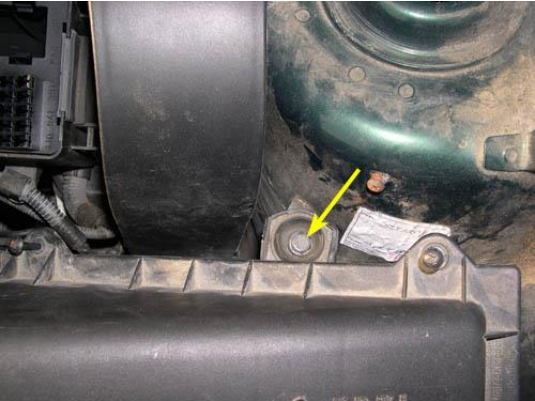

21. Unscrew the two Phillips head screws that hold the cover of the air filter box to the main section of the box. The screws are indicated by the yellow arrows in the picture below. You do not need to remove the screws completely, only unscrew them until they come out of the lower box (they can slide up 1/4"-1/2" easily when this point is reached).

22. The other side of the air filter box cover is held down by four tabs, indicated by the yellow arrows in the picture below. To remove the cover, you need to lift up on the rear slightly (red arrow in picture below) to release the tabs and then slide the cover towards the rear of the car (green arrow in picture below).

23. The picture below shows the air box with the cover removed and held up and to the side (be gentle - the intake hose is still connected), revealing the air filter element.

24. Disconnect the hard plastic hose for the secondary air injection system by pressing in on the two ribbed tabs (yellow arrows in picture below) and pulling the hose down and off. (FYI, the red arrows in the picture below indicate one of the tabs that hold the front of the air box cover in place.)

25. Lay the air box cover back on top of the air box (do not reconnect the cover) and then remove the rear 10mm bolt that attaches the air box to the car. The rear bolt is indicated by the yellow arrow in the picture below.

26. Remove the front 10mm bolt that attaches the air box to the car. The bolt is down between the air box and battery box - you'll need a long extension to get to it.

27. While holding the air box cover up and out of the way (a second pair of hands is helpful), slide the air box toward the passenger's side of the car and up and out of the car. The air box is secured on the driver's side by the intake snorkel (hole for snorkel can be seen in the picture below) and a rubber rod (yellow arrow in picture below). These make the air box difficult to remove.

Note: With the air box apart, now is a good time to replace your air filter element if it's been neglected.

28. With the air box now out, you should be able to see the driver's side tranny mount. It is indicated by the red arrow in the picture below.

RAISING THE ENGINE TO ACCESS THE WATER PUMP

WARNING: THE FOLLOWING STEPS REQUIRE THAT YOU DISCONNECT THE ENGINE/TRANNY MOUNTS FROM THE CAR. THERE IS ALWAYS THE POSSIBILITY THAT THE ENGINE/TRANNY MAY MOVE AND FALL WHILE IT IS DISCONNECTED. PLEASE BE VERY CAREFUL WHILE DOING THESE STEPS AND THEREAFTER UNTIL THE ENGINE/TRANNY IS RESECURED.

29. Reach under the car and remove the two 16mm bolts that secure the tranny pendulum mount to the tranny. These bolts are indicated by the yellow arrows in the picture below. The engine may rotate slightly when the bolts are removed, so be ready for this when you remove the second bolt. Also remember to keep track of which bolt goes where - the shorter bolt is towards the front of the car and the longer bolt is towards the rear.

30. Remove the front 16mm passenger's side engine mount-to-body bolt indicated by the yellow arrow in the picture below.

31. Remove the rear 16mm passenger's side engine mount-to-body bolt indicated by the yellow arrow in the picture below.

WARNING: MAKE SURE THAT YOU ONLY REMOVE THE BOLTS THAT CONNECT THE ENGINE MOUNT TO THE BODY!!! THESE BOLTS ONLY HOLD THE ENGINE MOUNT IN PLACE AND DO NOT SUPPORT THE WEIGHT OF THE ENGINE. DO NOT, I REPEAT, DO NOT REMOVE THE BOLTS THAT CONNECT THE ENGINE MOUNT TO THE ENGINE ITSELF (LOCATED BETWEEN THE ENGINE MOUNT AND THE ENGINE)!!! THESE BOLTS SUPPORT THE WEIGHT OF THE ENGINE. IF YOU REMOVE THEM WITHOUT SUPPORTING THE WEIGHT OF THE ENGINE FROM ABOVE OR BELOW, THE ENGINE WILL DROP!!! IF YOU WANT TO REMOVE THESE BOLTS, PLACE A JACK AND PIECE OF WOOD UNDERNEATH THE OILPAN FIRST!!!

32. Place a jack and piece of wood (for protection and to spread the load - a one foot long 2x6 is a good choice) under the passenger's side of the oilpan. Make sure the wood is against the flat part of the oil pan (yellow arrows in picture below) and not against the sloped part (red arrow in picture below). Also make sure to avoid placing the piece of wood up against the bump in the oilpan where the drain plug screws into (green arrow in picture below). If the engine is jacked up with the wood against this bump, it will concentrate the load of the engine on this spot and could possibly damage the oilpan.

33. IT'S FINALLY TIME TO JACK UP THE ENGINE!!! The picture below shows the height of the engine before lifting. Note that the engine cover (yellow arrow) is roughly even with the front end trim.

NOTE: THE DRIVER'S SIDE TRANNY MOUNT HAS NOT BEEN DISCONNECTED YET. THIS WILL BE PERFORMED AFTER LIFTING THE PASSENGER'S SIDE OF THE ENGINE.

34. Slowly jack up the passenger's side of the engine. If the car is on the ground or on ramps (suspension is still loaded), then both the car and engine will lift up initially as the engine is raised since the suspension is being unloaded. After the suspension is unloaded, the engine will rise by itself and the car body will remain at the same height. If the car is on stands, then the above will not occur - the engine will begin to rise immediately.

35. The engine can be jacked up approximately 1 3/4" before binding will occur. I don't recommend jacking the engine up anymore than this or you may possibly damage parts of the engine or exhaust system. Most notable are the oxygen sensors on the catalytic converter. If the engine is raised any further, the sensor leads will smash into the underside of the car and possibly be damaged. The additional clearance gained by raising the engine 1 3/4 " is just enough to get the water pump out - you shouldn't need to raise it any further.

WARNING: IF THE ENGINE OR EXHAUST BINDS BEFORE REACHING 1 3/4" OR SO (I.E., THE CAR STARTS LIFTING AGAIN AS THE ENGINE IS JACKED UP), THEN STOP IMMEDIATELY AND LOWER THE ENGINE BACK DOWN SLIGHTLY. BEFORE JACKING UP THE ENGINE AGAIN, DETERMINE WHAT IS PREVENTING THE ENGINE FROM BEING RAISED AND CORRECT THE PROBLEM.

36. The pictures below show that the top of the engine and the passenger's side engine mount were raised approximately 1 3/4" before binding occurred.

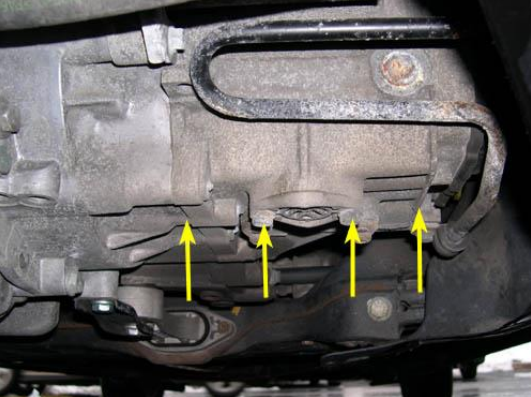

37. Even with the engine now jacked up, it is still necessary to slide the entire engine and tranny over towards the driver's side of the engine to get the water pump out of the block. Place a second jack and piece of wood underneath the tranny. Try to find a nice flat area where the block of wood can apply force the the tranny evenly. Such an area is indicated by the yellow arrows in the picture below.

38. Jack up on the tranny very slightly, just enough to support the weight once the tranny mount bolts are loosened, not enough to actually jack up the tranny.

WARNING: DO NOT PERFORM THE NEXT STEP WITHOUT MAKING SURE THAT THE JACK/WOOD IS IN PLACE UNDERNEATH THE TRANNY. THE NEXT STEP INVOLVES LOOSENING THE BOLTS THAT SECURE THE TRANNY MOUNT TO THE TRANNY. IF THE JACK/WOOD IS NOT IN PLACE, THE TRANNY WILL DROP AND COULD POSSIBLY CAUSE THE ENGINE TO FALL.

39. Loosen the two 18mm tranny mount-to-tranny bolts (indicated by the red arrows in the picture below) approximately 1". You do not need to remove them completely. When you do this, the engine may shift slightly towards the driver's side of the car since the tranny mount-to-tranny bolts actually sit in slots in the tranny mount. This is a good thing as it gives more clearance for getting the water pump out. Make sure that tranny does not hang by the loosened bolts. If necessary, adjust the height of the jack under the tranny so that the weight of the tranny is supported by the jack.

40. Push the engine/tranny over towards the driver's side as far as it will go. It may be helpful to have someone lift and pull the tranny over from the driver's side of the car while someone else pushes the engine over from the passenger's side.

REPLACING THE WATER PUMP

41. With the engine raised and pushed over towards the driver's side, it should now be possible to remove the water pump from the block and install a new one. While it is possible to unbolt the pump from the block without first removing the belt pulley (there are holes in the pulley which provide access to the pump bolts behind it), there is still not enough clearance to remove the pump and pulley together. Therefore, you must first remove the pulley and then remove the pump. (On a MKIII, you can remove both together since the motor mount support is not in the way, but on MKIV the pulley and pump must be removed separately.)

NOTE: PLEASE READ STEPS 42 THROUGH 44 BEFORE ATTEMPTING TO REMOVE THE PULLEY BOLTS.

42. The picture below shows a socket wrench and 6mm hex socket being used to remove the pump pulley bolts (yellow arrows). You can also use a regular hex wrench, but the socket seems to work better. Be warned that the heads on the pulley bolts are extremely shallow and can strip easily. Make sure that you insert the hex socket/wrench into the bolt head completely and apply side pressure to help prevent stripping from occurring. It is also a good idea to spray the bolts with a penetrating lubricant prior to removal.

43. If you are using a socket wrench with a hex socket to remove the pump bolts, you will need to rotate the pulley until the bolt being removed clears the motor mount frame support, as show in the picture above. The other two bolts will be blocked by the frame support and the pulley will need to be rotated again (and again) to get the other bolts out. To rotate the pulley, the tension on the serpentine belt needs to be removed temporarily. To do this, follow steps 3 and 4 in the following DIY - SERPENTINE BELT DIY. If you are using a regular hex wrench to remove the pulley bolts, there may be enough clearance between the pump and motor mount frame support to remove the bolts without having to rotate the pulley.

44. While each pulley bolt is being removed, the pulley must be held in place and kept from spinning. There are two easy ways to accomplish this. The first is to use the force applied by the tightened serpentine belt to hold the pulley in place while the bolts are loosened. (Note: If belt tension is not sufficient to keep the pulley from spinning while removing the pulley bolts, use the next method.) The second is to loosen the belt on the pulley (refer to steps 3 and 4 in the serpentine belt DIY) and insert something into one of the pump bolt access holes (indicated by the yellow arrow in the picture below), such as a small hex wrench, to pin the pulley against the block and keep it from spinning. Either works well.

45. Once the pulley has been removed from the pump, remove the serpentine belt tensioner in order to provide more clearance for removing the pump from the block. To do this, follow steps 3 through 5 in the serpentine belt DIY.

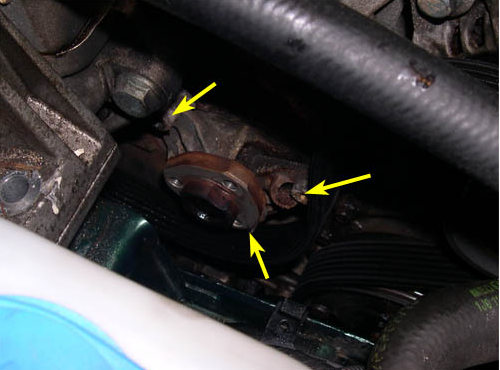

46. Remove the three 6 mm hex bolts that attach the water pump to the block. These bolts are indicated by the yellow arrows in the picture below. Again, be careful not to strip the bolts while removing them.

47. More than likely, the pump will not come out of the block easily once the bolts are removed. If it doesn't, use a large screwdriver or other similar object to carefully pry the pump from the block. Once dislodged, it should slide out easily. If you did not drain the coolant from the block, coolant will spill out as the pump is removed. If the pump will not slide out completely, you may need to twist it slightly to clear the motor mount frame support or you may need to push the engine over towards the driver's side some more.

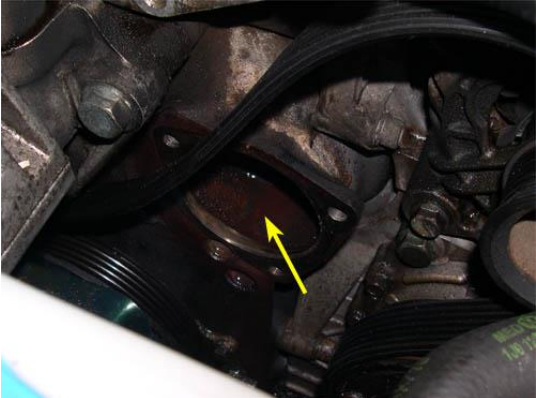

48. Once the pump is out, you should see a big hole in the block, as indicated by the yellow arrow in the picture below.

49. Check to make sure that all of the fins on the existing pump impeller are still intact. If some have broken off, check inside the pump hole to see if they are in there. If not, that means they have traveled into the cooling system and are stuck somewhere. There is no easy way to retrieve the pieces except to disassemble and inspect parts of the cooling system, such as the thermostat and radiator. When I removed my pump, I discovered that one of the impeller fins had broken off. I didn't feel like spending the time and effort to find it so I just left it in the system. I'm not going to worry about it unless I have cooling system problems.

50. Prior to installing the new water pump, clean the pump mating surface around the hole in the block with a rag or paper towel to remove any junk.

51. Lubricate the new o-ring for the new pump with some coolant and install it in the groove on the pump. Next, install the new pump into the block, line up the bolt holes (they only line up one way), insert the bolts and tighten to 11 ft-lbs. We put some anti-seize on the bolt threads to make sure they'd come out easy next time (although hopefully there won't be a new time).

52. Install the belt pulley on the new pump, insert the bolts and tighten to 18 ft-lbs. We put some Loctite on the pulley bolts to help ensure that the pulley didn't come flying off the pump while spinning at thousands of RPMs.

53. Reinstall the serpentine belt tensioner, make sure the belt is on all of the pulleys correctly and reapply tension to the belt.

54. You should now have a new, fully-functional water pump. Now lower the engine, reattach the tranny and engine mounts and reinstall all of the parts that were moved or removed by following steps 3 through 40 in reverse.

55. The torque specs for the engine and tranny mount bolts are as follows:

- passenger's side engine mount-to-body bolts - 30 ft-lbs + 90° (stretch bolt)

- pendulum mount-to-tranny bolt, front - 30 ft-lbs + 90° (stretch bolt)

- pendulum mount-to-tranny bolt, rear - 30 ft-lbs

- driver's side mount-to-tranny bolts - 44 ft-lbs + 90° (stretch bolt)

56. That's it. Enjoy the fact that you just saved a ton of money by doing this yourself!

Most Popular

-

1

-

2

-

3

-

4

-

5