Loading... Please wait...

Loading... Please wait...12V VR6 Timing Chain and Guides Replacement

Please give credit where credit is due! This DIY was completed ENTIRELY by the hardest working VW Vortex moderator on the site!! Gary Thompson, Ph.D. - vortex ID VGRT6, email address vgrt6@yahoo.com. Please make sure to say thanks to Gary, and if you ever see him at a bar, buy em a beer. These DIY's are more complete than anything Bentley has ever written!!

REPLACING TIMING CHAINS, TENSIONERS AND GUIDES ON A MKIV 12v VR6

The following DIY outlines the procedure for replacing timing chain parts on a MKIV 12v VR6 engine.

NOTE: If you are using this DIY to reinstall an upper chain and time the engine after a head rebuild or headgasket replacement (i.e., the head came off, but everything else was left in place), make sure to read the section pertinent to this topic in the DIY UPDATES at the end of the DIY!!!

Before getting started - refer to the following few paragraphs about the triple square tool - you will need this :

I was going to post this a while back, but forgot. These bits came up in a recent thread and reminded me to post this info.

If you need triple square bits (like Torx bits but with 12 points instead of 6 - also called serrated or 12-point bits) in order to remove things like a flywheel or axle bolts, you can buy K-D bits from your local Napa Auto Parts store (can also buy them on-line).

The Napa part numbers are as follows:

8mm - SER2304 - $4.99

10mm - SER2305 - $5.49

12mm - SER2306 - $5.99

AFAIK, there is no 6mm bit available (part number SER2303, which is the logical part number in the sequence, does not exist).

Whatever you do, do NOT buy the Lisle set of triple square bits that PepBoys sells ($15 for 6, 8, 10 and 12mm). I made the mistake of purchasing this set in order to remove and reinstall my flywheel and axle bolts during a recent timing chain adventure. The teeth on 10mm bit from this set were deformed so badly after torquing just 3 of 10 flywheel bolts that it was completely unusable. I ended up taking the whole set back to PepBoys and demanding my money back. The Napa bit (SER2305) was used to torque the remaining 7 flywheel bolts and all of the axle bolts (they're 10mm on the MKIV cars) and it looked like it had barely been used afterwards.

Since timing chains are considered by VW to be a "lifetime" item, there is no recommended mileage for the replacement (or even inspection) of timing chain parts. However, while timing chains should realistically out last the rest of the car, the design of the guides and tensioners used to keep the chains tight on a 12v VR6 is inadequate IMO. It is very common for guides and tensioners to fail (especially in older VR6 motors) as mileage approaches or passes 100k miles. Unfortunately, failed guides or tensioners may cause a chain to jump a tooth or more on a sprocket or may even cause a chain to snap. If either were to happen, serious damage to the engine would result as valves slam into pistons at high speed.

While there is no definitive indication that timing chain parts should be inspected and/or replaced, the most common sign of trouble is a rattling sound from the driver's side of the engine that occurs between 1000 and 1200 RPMs. This sound has been described most often as "marbles in a can" or like a sewing machine (see below for sound clip of noise). When the timing chain parts are in good working order, the chains are under considerable tension and NOTHING should be loose enough to rattle. If you hear a rattling noise, and it's coming from one or more of the timing chain parts, it most likely indicates that these parts are either loose or broken and should be repaired ... or else!

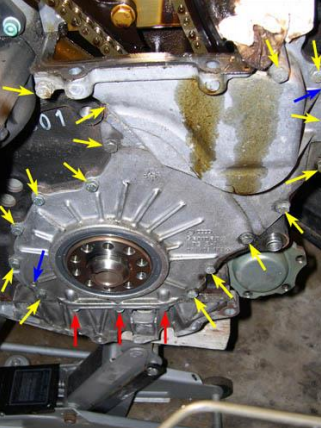

The timing chain setup on a VR6 consists of an upper and lower chain. The upper chain connects the camshaft sprockets to an intermediate shaft sprocket (outer sprocket) and the lower chain connects a second intermediate shaft sprocket (inner sprocket) to the crankshaft sprocket. The camshaft sprockets have 27 teeth, the crankshaft sprocket has 24 teeth and the inner and outer intermediate shaft sprockets have 32 and 18 teeth, respectively. The ratio between the camshaft and outer intermediate sprockets is 3:2 (or 27:18) and the ratio of the inner intermediate shaft and crankshaft sprockets is 4:3 (or 32:24). This yields a ratio between the camshaft and crankshaft sprockets of 2:1 - i.e., the crankshaft rotates twice for every one rotation of the camshaft.

Each timing chain has a guide rail (curved on the upper chain, straight on the lower chain) and tensioner rail to keep them tight. The lower tensioner rail is a one-piece, spring-driven unit, while the upper tensioner is a two-piece design consisting of a tensioner rail and a separate tensioner bolt.

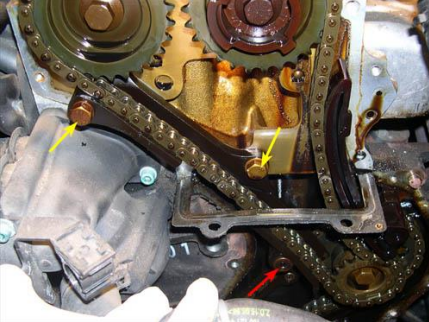

There are actually two versions of the upper timing chain setup. The early version used a double-row chain, a two-piece tensioner rail (phenolic plate(?) riveted to a metal backing) and a tensioner bolt that relies solely on oil pressure to apply force to the tensioner rail (the bolt has a bleed hole in the end to help regulate the amount of force applied). Because of an unusually high rate of wear of the upper tensioner rail (many are completely worn through the phenolic to the metal backing plate by 100k miles), the upper chain parts were replaced during the '97 model year with an "improved" setup consisting of a single-row chain, a single-piece, dense polymer tensioner rail and a tensioner bolt that uses both spring tension and oil pressure to apply force to the tensioner rail (spring tension extends the bolt to a minimum length, around 18mm, and then oil pressure extends the bolt to it's final position - this tensioner bolt does not have a bleed hole to regulate oil pressure). According to the ETKA CD, the switchover point between the older and newer upper chains setups is determined by engine production number and is as follows:

old setup - AAA engine #217000 and before

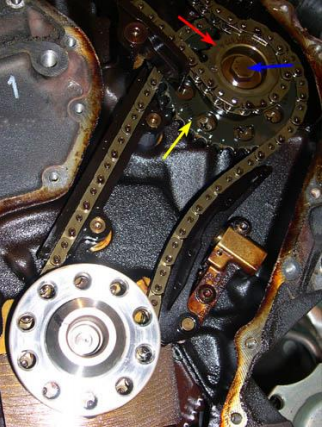

new setup - AAA engine #217001 and after

If you have an AAA VR6 and don't know where to look for the engine production number, then please read this THREAD.

The newer setup lasts considerably longer. When I replaced my timing chain parts at nearly 150k miles, the upper tensioner rail had grooves in it from the chain that were only a fraction of a mm deep. IMO, the rail would have easily last to 500k to 1M (million) miles based on how slowly it was wearing.

The lower chain parts are the same on all 12v VR6s - AFAIK, no changes to them have been made during the production of this engine.

The procedure below was based on a '99.5 MKIV Jetta GLS 12v VR6, which has the newer-style upper timing chain parts. While the older and newer upper parts are slightly different in both form and function, the procedure for replacing them is the essentially the same on all 12v VR6s. Therefore, the procedure below should be generally valid for any vehicle with a 12v VR6 engine. For those older VRs with EGR systems, you will have to deal with the removal of some EGR components from the top, rear of the engine in order to access the timing chains. Newer VRs do not have to worry about this however. If your VR has an EGR system, make sure to see the section devoted to this in the DIY UPDATES section at the end of the DIY. (Note: Torque specs given in this DIY are from the MKIV Bentley manual - these torque values may be slightly different on earlier model 12v VR6 engines.)

The procedure assumes that the transmission, clutch, flywheel, upper intake manifold and other small parts (coilpack, TB, airbox ...) have been removed from the car and that other steps necessary to remove these have also been performed (front end of car raised, battery disconnected, etc). The removal of these parts on a MKIV VR6 will be covered in detail in a separate DIY - a link to this DIY will be posted here when it is finished.

NOTE: If you are only replacing the upper tensioner bolt and/or upper guide rail, you do not need to remove the transmission, clutch, flywheel, etc. You can replace this part by only removing the upper intake manifold (and other associated parts) and then following steps 1 through 20 below. To replace the upper tensioner bolt, you do not need to remove anything. Simply follow steps 10, 48 and 52 to remove and install the bolt.

Please do the procedure at your own risk and be ready to make small adjustments while doing them. Also, please be observant while removing parts so that they go back together correctly. The procedure is fairly involved and extreme care should be taken while performing it. SEVERE engine damage WILL result if it is not performed correctly. Depending on how mechanically inclined you are, it should take somewhere between 2 and 8 hours to perform.

The tools needed to perform the procedures are:

1) 10mm, 13mm, 15mm and 27mm sockets or wrenches

2) 5mm and 6mm hex sockets or wrenches

3) spark plug socket

4) large flathead screwdriver

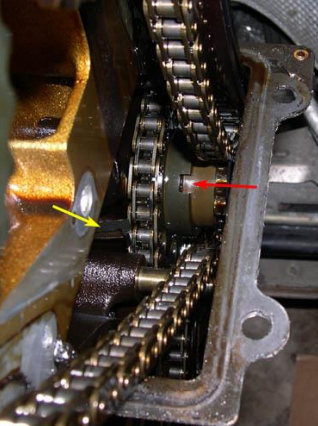

5) torque wrench(es) valid for the range of 89 in-lbs to 74 ft-lbs.

6) VW camshaft locking tool (#3268) or 1/8" metal or dense plastic plate

7) RTV sealant (ultra-grey, sensor-safe)

8) pieces of wood for removing and installing rear main oil seal

9) container and oil

The VW part #s for the parts replaced in this DIY are:

* 021 109 503 D - upper timing chain

* 071 109 513 - upper timing chain guide rail

* 021 109 509 E - upper timing chain tensioner rail

* 021 109 507 B - upper timing chain tensioner bolt (comes with copper crush washer N 013 827 1)

* 021 109 465 B - lower timing chain

* 021 109 469 - lower timing chain guide rail

* 021 109 467 - lower timing chain tensioner rail

* 068 198 171 - rear main oil seal

Note: The above part #s for the upper timing chain parts are for the newer style parts. For the part #s valid for engines with the older style upper timing chain parts, refer to James' 12V VR6 headgasket/timing chain/cooling system parts list.

All of the above parts were purchased from http://www.vwparts.com and http://www.germanautoparts.com. Some parts were cheaper from one source while others were cheaper from the other. All parts that I received from these two vendors were OEM.

Special thanks go to James (James 93SLC - luckily he had done this procedure before on his Corrado), Shashi (DJ-SBK) and Eric (BCDS2003T), for their help with the procedure. I'd also like to thank James and Beth for hosting the pics in this DIY on their website.

REMOVING OLD TIMING CHAIN PARTS

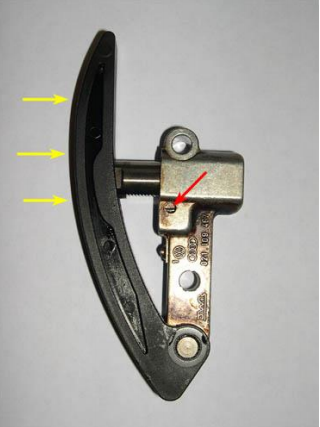

1. Unclip the fuel lines (yellow arrows) and rear knock sensor wire (red arrows) from the top of the valve cover, as shown in the picture below (this may not be necessary on all engines).

2. Loosen and/or remove the ten (10) 10mm bolts/nuts that secure the valve cover. On a MKIV, there are 8 captured bolts (yellow arrows in picture below) and 2 nuts on posts (red arrows in picture below). I believe that all ten are nuts on posts on other VR6 engines, but I may be wrong. Once the valve cover is unsecured, pull it up and off of the head, being careful not to damage the cover gasket (it will be reused).

3. The images below show the two camshafts. On the passenger's end are grooves that are used for timing the engine (yellow arrows) and on the driver's end are the camshaft sprockets and upper timing chain.

CAUTION: Once the valve cover is off, be careful not to drop any tools or small parts into the engine.

4. Remove all six (6) spark plugs if you haven't already done so.

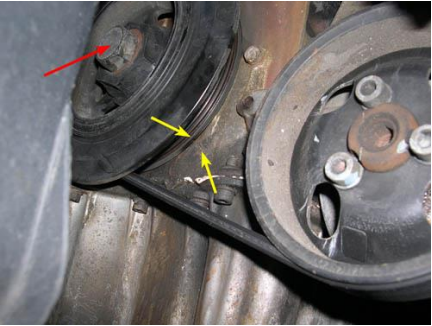

5. Crank the engine to Cylinder #1 TDC (top dead center) by slowly hand-turning the crankshaft pulley (red arrow in picture below) clockwise with a 27mm wrench or socket until the little notch on the inner flange of the pulley lines up with the timing mark on the block (yellow arrows in picture below).

NOTE: When doing gross rotations of the crankshaft, always turn the crankshaft the same direction that it rotates when the engine is running (clockwise in the picture below). It's OK to rotate it the opposite way for small adjustments only.

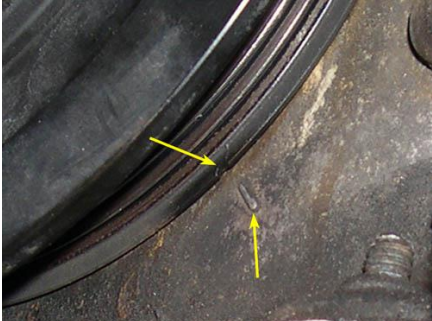

6. The picture below shows a close-up of the notch and timing mark that need to be lined up to set the engine at Cyl. #1 TDC.

7. Once the notch and timing mark are lined up, check the groove on the end of one of the camshafts. The groove should be above the centerline of the shaft - i.e., there should be more material below the groove (yellow arrow in the picture below) than above the groove (red arrow in picture below). If the opposite is true, then the camshafts are 180° out of phase. Rotate the crankshaft one full revolution and line up the notch and timing mark again to set the camshafts for Cyl. #1 TDC (remember, two rotations of the crankshaft equals one rotation of the camshafts).

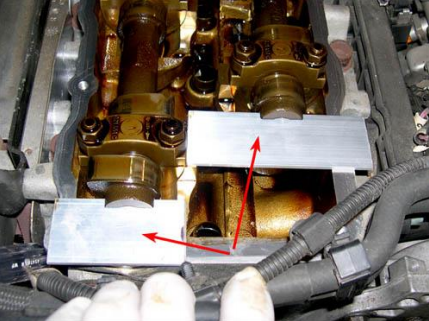

8. If everything is lined up properly and the engine is at Cyl. #1 TDC, you should be able to slide the camshaft locking tool (VW tool #3268) into the grooves. Instead of using the VW tool, I just used two 1/8" thick pieces of Al plate (purchased at Lowe's) to lock each camshaft individually, as shown by the red arrows in the picture below. You can use pretty much any 1/8" thick metal or dense plastic plate for this purpose.

NOTE: Since the MKIV VR6 has captured bolts that secure the valve cover, no holes need to be drilled in the plate(s) for them to slide into place. However, on earlier VR6s, holes will need to be drilled in the plates so that the plates will fit over the posts that the valve cover is secured to (the VW locking tool already has holes drilled in the necessary places). Also, if you do not use the VW camshaft locking tool, make sure to secure whatever you use so that it can not fall into the engine. The VW tool can not fall into the engine, but something smaller may be able to. I used packing tape attached to the Al plates and wrapped around the fuel lines to keep the plates from accidentally slipping into the block.

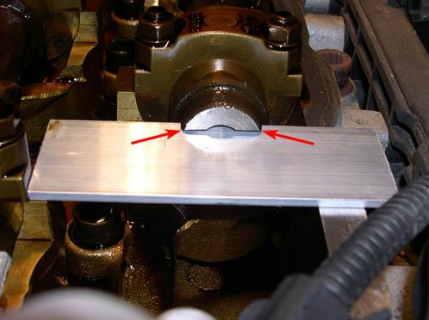

9. If the engine is timed correctly, the camshaft tool(s) (VW or improvised) should slide into the groove easily and should be exactly parallel to it. The picture below shows that the gaps between the groove and tool on either side of the camshaft should be equal.

NOTE: Leave the VW or other improvised camshaft locking tool in place in the camshaft grooves until instructed to remove it. This will keep the camshafts from rotating when the upper chain is removed, maintaining the correct valve timing.

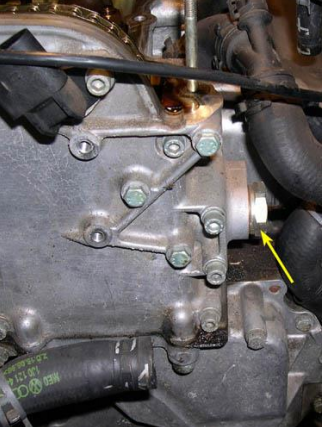

10. Remove the upper tensioner bolt (yellow arrow in the picture below) from the back edge of the upper timing chain cover using a 27mm wrench or socket.

WARNING: Do NOT rotate the engine with the upper tensioner bolt removed. Doing so may cause the upper timing chain to jump a tooth or more and would throw off the engine timing. If you are replacing all of the timing chain parts, then this is no big deal since you'll be resetting the timing anyway. However, if you are only replacing the upper tensioner bolt and/or upper guide rail, messing up the timing may result in you having to remove the transmission, clutch, flywheel and lower timing chain cover in order to access and re-time the intermediate shaft.

11. The picture below shows the newer style upper tensioner bolt. There should be a copper crush washer (blue arrow) present to seal the bolt against an oil leak. (Note: Even though the tensioner bolt and crush washer have separate VW part #s, the parts are one piece on the newer style tensioner.)

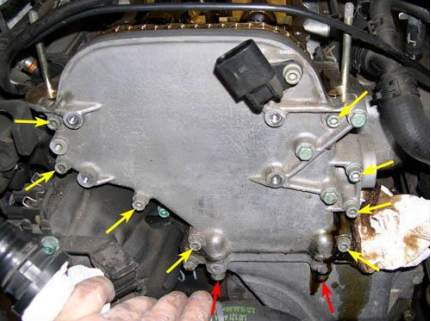

12. Remove the bolts that secure the upper timing chain cover. There are eight (8) 5mm hex bolts (yellow arrows in picture below) that secure the cover to the head and two (2) 6mm hex bolts (red arrows in picture below) that secure the upper and lower timing chain covers to each other (with part of the headgasket between them - this will be covered in more detail below).

13. Carefully pry the upper timing chain cover away from the head and lower timing chain cover. Be extra careful not to damage the part of the headgasket that extends out from beneath the head and between the two chain covers. This is critical since the headgasket will be reused (unless you are removing the head and will be replacing the entire gasket).

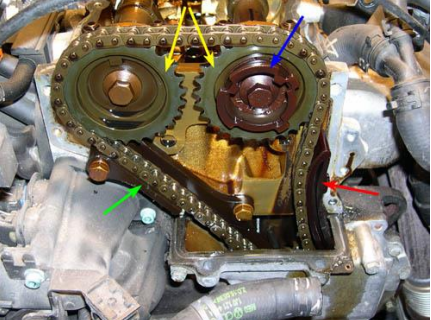

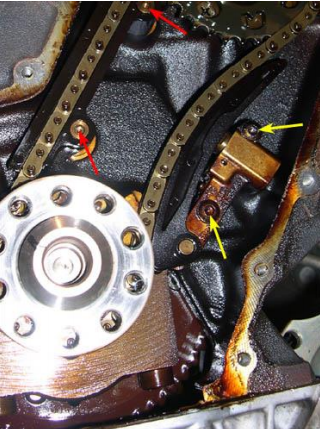

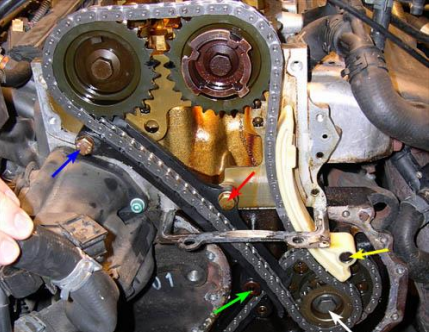

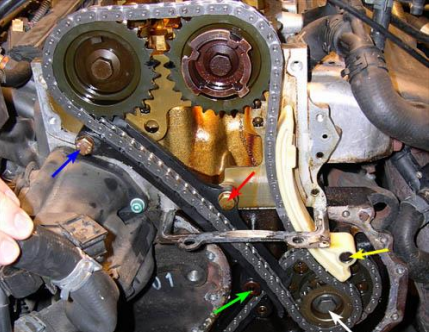

14. With the upper timing chain cover off, you should be able to see most of the upper timing chain parts, as shown in the picture below. The yellow arrows point to the two camshaft sprockets, which are secured to the camshafts with 15mm bolts. The blue arrow points to the shutter wheel on the rear sprocket that is used by the camshaft position sensor (this wheel may be slightly different on earlier model VR6s). The green arrow points to the upper guide rail and the red arrow points to the upper tensioner rail.

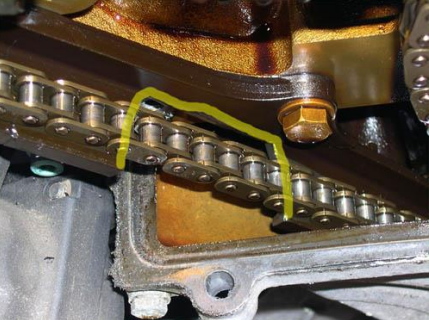

15. The picture below shows a close-up of my original upper guide rail. The yellow shading shows the location of a piece that broke off and was causing the rattling noise heard in the sound clip in the link above.

16. If you are only replacing the upper guide rail, skip steps 17 through 19 and go directly to step 20. Otherwise, continue on with the next step (#17).

17. Remove the bolts that secure the lower timing chain cover. There are sixteen (16) 10mm bolts (yellow arrows in picture below) that secure the cover to the block and three (3) 5mm hex bolts (red arrows in picture below) that secure the lower timing chain cover to the oil pan. The blue arrows indicate the position of guide pins used to locate the cover when reinstalling it. NOTE: It has been pointed out by ubercruizinvr6 that the lower part of the thermostat housing on pre-MKIV VR6s needs to be loosened/removed in order to remove the top front lower timing chain cover bolt (above the '01' in the picture below) - see pages 3 and 4 of this DIY thread and/or the DIY UPDATES section below for more info.

18. Carefully pry the lower timing chain cover away from the block and oil pan. Again, be extra careful not to damage the part of the headgasket that extends out from beneath the head and between the two chain covers.

19. With the upper timing chain cover off, you should be able to see all timing chain parts, as shown in the picture below. The yellow arrow points to the part of the headgasket that normally resides between the two timing chain covers, but is now completely unprotected. Be extra careful not to damage/bend the gasket during the replacement procedure below.

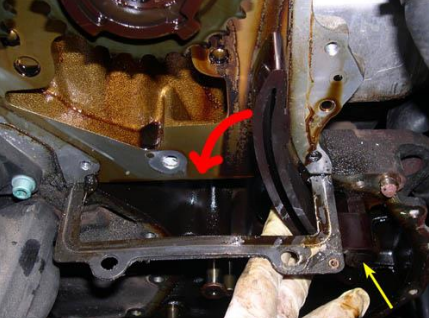

20. Remove the upper guide rail by removing the two (2) 13mm bolts (yellow arrows in picture below) and then sliding the rail up and off of the lower guide post (red arrow in picture below). You do not need to remove the guide pin. (Note that the guide pin resides behind the lower chain cover - I suspect that VW used a guide pin instead of a bolt here so that the guide could be replaced without having to remove the lower cover, and consequently, the tranny, clutch, etc).

NOTE: If you are only replacing the upper guide rail, perform step 29 and the appropriate portion of step 35 to install the new guide. Once the guide is installed, perform the engine timing check in steps 40 through 43. Finally, perform steps 48, 49 and 51 through 57 to reassemble everything.

TIP: I recommend that you label bolts as you remove them. Many of the bolts are diameter and length specific to a location and will not fit in other locations.

21. The picture below shows the notch in the inner intermediate sprocket (red arrow) that should be visible when the intermediate shaft is timed correctly (MKIV Bentley step #7 and Figure #21 on page 15d-16). Also, the yellow arrow points to the piece of my upper guide rail that broke off and was rattling in between the block and the inner intermediate sprocket.

22. In order to remove both the upper and lower timing chains, it is necessary to create some slack in the chains. The easiest way to accomplish this in both chains is to remove the intermediate sprockets. In the picture below, the yellow arrow points to the inner intermediate sprocket and the red arrow points to the outer intermediate sprocket. To remove the sprockets, remove the 15mm bolt (blue arrow in picture below)that secures the sprockets to the intermediate shaft. In order to do this, it is necessary to counterhold the crankshaft to keep it at Cyl. #1 TDC. You can use one of the special VW tools to do this, or you can just have a friend counter hold the crankshaft pulley with the 27mm wrench or socket and a long breaker bar. The intermediate shaft bolt is torqued on fairly tight (74 ft-lbs or 100 N-m), so it will take a good amount of force to loosen it. If the crankshaft accidentally moves slightly while loosening the bolt, turn the crankshaft back to Cyl. #1 TDC BEFORE removing the intermediate bolt and sprockets. (Note: Leave the camshaft locking tool in place while loosening the intermediate shaft bolt. As long as the crankshaft does not move significantly, there is no harm in leaving the tool in the camshaft grooves.)

23. Slide the outer intermediate sprocket off of the inner intermediate sprocket and then remove the upper chain from the camshaft sprockets. (Note that the inner and outer sprockets are keyed so that they will only fit together one way).

24. With the upper chain removed, the upper tensioner rail should fall down through the hole in the exposed headgasket, as indicated by the red arrow in the picture below. The tensioner rail pivots on a pin, which is indicated by the yellow arrow in the picture below.

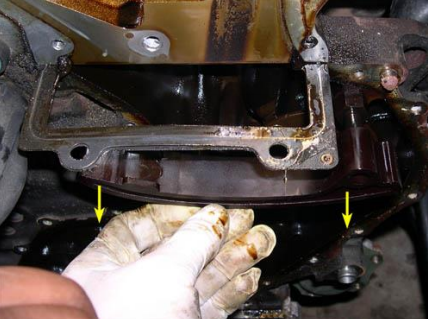

25. To remove the upper tensioner rail, simply slide it off of the pivot pin, as indicated by the yellow arrows in the picture below. You do not need to remove the pivot pin.

26. Remove the lower tensioner unit by removing the two (2) 5mm hex bolts indicated by the yellow arrows in the picture below (the tensioner will fully extend when removed if you don't hold the rail and body together or secure it with a U-clip like the one that comes with a new tensioner).

27. Slide the inner intermediate sprocket off of the intermediate shaft (note that the shaft is also keyed so that the sprocket only goes on one way) and then remove the lower timing chain from the crankshaft sprocket. Finally, slide the lower guide rail off its guide pins, which are indicated by the red arrows in the picture above. You do not need to remove the guide pins.

28. All of the timing chain parts that need to be removed should now be removed

INSTALLING NEW TIMING CHAIN PARTS

29. Clean ALL of the mating surfaces of the timing chain covers, head, block and headgasket of oil and silicone gasket material. Examples of these areas are indicated by the red shading in the picture below. On a MKIV 12v VR6, there are two (2) 3mm holes in the headgasket right next to the head/block (yellow arrows in picture below). Remove any gasket material that is in these holes. Also be sure to clean out any oil from the central upper guide rail bolt hole (green arrow in picture below). Locking compound is used on this bolt to ensure that it does not back out and catch on the upper timing chain and it is critical that the bolt hole be clean and dry. Finally, the blue arrow in the picture below points to the oil feed hole for the upper tensioner bolt. Make sure that this hole is not clogged/blocked with gasket material (it shouldn't be, but check anyway)!

30. Before installing new timing chain parts, double check that the crankshaft is timed correctly. If the crankshaft is timed correctly, a ground tooth on the crankshaft sprocket (yellow arrow in the picture below) should line up exactly with the split in the main crankshaft bearing cap (red arrow in the picture below). This should be the case when the engine is at Cyl. #1 TDC (i.e., the notch on the crankshaft pulley and the timing mark on the block are lined up as shown in steps 5 and 6).

31. The picture below shows a close-up of the ground tooth (yellow arrow) and bearing split (red arrow). Note the difference between the ground tooth and the "normal" teeth adjacent to it (blue arrows).

32. Slide the inner intermediate sprocket onto the intermediate shaft and rotate the sprocket until the pointer in one of the sprocket holes (yellow arrow in the picture below) lines up exactly with the vertical mark on the intermediate shaft thrust washer behind the sprocket (red arrow in the picture below). The intermediate shaft is timed correctly when the pointer and washer mark are lined up. You can use the vertical mark either at the 6 o'clock position (as shown) or the 12 o'clock position. It doesn't matter - either will result in the engine being timed correctly. Note: The picture below was taken out of sequence, and as a result, shows the lower chain, outer intermediate sprocket, intermediate sprocket bolt, lower guide rail and upper guide rail already installed. They should not be installed at this point in the procedure. Please disregard this discrepancy between the text and photo.

33. Slide the new lower guide rail onto its guide posts (green arrows in picture below).

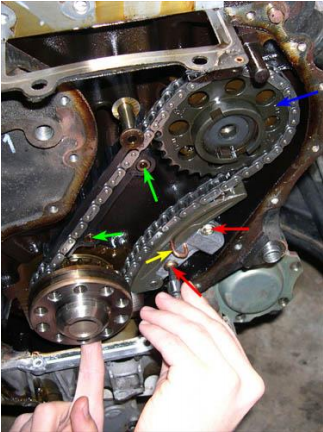

34. Install the new lower timing chain onto the crankshaft sprocket, slide it into the lower guide rail and then over the inner intermediate sprocket (blue arrow in picture above). Make sure that all of the slack is on the rear side of the chain and that the crankshaft and intermediate shaft timing marks are still lined up correctly. Next, install the new lower tensioner unit and torque the two tensioner bolts (red arrows in picture above) to 89 in-lbs (10 N-m). Finally, check again that the timing marks are lined up correctly and then remove the u-clip used to keep the tensioner fully compressed during installation (yellow arrow in picture). This will apply tension to the lower chain. NOTE: Be very careful not to accidentally pull the inner intermediate sprocket off of the intermediate shaft after the u-clip is removed or the lower tensioner will fully extend.

TIP: If your lower tensioner is fully extended (as shown in the picture below), it needs to be fully compressed, or reset, before installation. To do this, use a small screwdriver or similar tool to slide the ratcheting mechanism in the hole in the tensioner body (red arrow in picture below) toward the pivot point between the body and tensioner rail and then push in on the rail (yellow arrows in picture below). Remember, if you let go of the rail it will fully extend again. Either hold it in place with a U-clip or by hand until it is installed.

35. Slide the new upper tensioner rail onto its pivot pin (yellow arrow in picture below) and rotate the rail clockwise through the hole in the headgasket. Use a piece of tape or something similar to temporarily hold the rail in the upright position (remove the tape after the upper timing chain and outer intermediate sprocket have been installed). Next, install the new upper guide rail by sliding it onto it's guide pin (green arrow in picture below) and then installing the two (2) 13mm bolts (red and blue arrows in picture below). Use Loctite (blue - med. strength) on the central, shorter bolt (red arrow) and torque both bolts to 15 ft-lbs (20 N-m).

36. Install the upper timing chain across the two camshaft sprockets (the chain should be tight between them) and then down between the upper guide rail and tensioner rail and through the hole in the headgasket, as shown in the picture above. Next, install the outer intermediate sprocket (with the upper chain wrapped around it), making sure that the chain is still tight between the two camshaft sprockets, is tight against the upper guide rail and ALL slack is on the rear side of the chain adjacent to the tensioner rail. Remember that the sprocket is keyed and can only match up with the inner intermediate sprocket one way - it may be difficult to mate the inner and outer sprockets - do NOT move the lower chain assembly to get the sprockets to match up. Finally, check again to make sure that the timing marks are all lined up. If they are, install the intermediate shaft bolt (white arrow in picture above) and torque to 74 ft-lbs (100 N-m) - remember to counterhold the crankshaft again when doing this, as was done in step 22.

37. Remove the u-clip from the lower tensioner unit if you haven't already done so.

38. Check again to make sure that the timing marks are lined up (you can never do it enough times! ).

39. The new timing parts should now be correctly installed, as shown in the picture below.

40. Before sealing everything back up, it is a good idea to test out the timing of the engine. To do this, the upper timing chain cover and upper tensioner bolt need to be temporarily reinstalled. Reinstall the upper timing chain cover (be careful not to damage the headgasket) and secure it to the head with four (4) or more of the 5mm hex bolts (it's not necessary to use all eight of them). Next, install the upper tensioner bolt - thread it in fully and tighten it hand-tight (there's no need to torque it to full spec for this test).

41. Remove the cam locking tool (or plate(s)) from the grooves in the camshafts.

42. Using the 27mm wrench or socket, rotate the crankshaft clockwise two (2) full rotations and then line up the timing marks on the crankshaft pulley (notch on pulley and mark on block - see steps 5 and 6). This will cause the camshafts to rotate one (1) full rotation. If the engine is timed correctly, you should be able to slide the cam locking tool (or plate(s)) back into the grooves in the camshafts. If this does occur, then you've timed the engine properly and you can seal things up. Congratulations. If this does not occur, then there is a problem with the engine timing. You'll either need to figure out what is wrong and fix it, or remove everything and start again from scratch. If you've been checking the timing marks throughout the installation procedure as suggested, the engine will most likely be timed correctly.

43. Remove the upper tensioner bolt and upper timing chain cover.

44. Since the lower timing cover is off, it is a good idea to replace the rear main oil seal, especially if the engine has significant mileage on it or you noticed some oil leakage when the transmission was removed. If you are not going to replace the rear main seal, go directly to step 48.

45. To remove the old rear main seal (yellow arrow in picture below), support the lower timing chain cover with a few pieces of wood with the inside surface of the cover facing up, as shown below. Using a screwdriver or other similar tool and a hammer, carefully pound the old seal out of the cover. The old seal may be in there tight, so you may have to pound pretty hard to get it out. Be careful not to mar the mating surface of the timing cover or the new seal may not seal properly when installed. Just take you time and pay attention and it should come out without any problems.

46. To install the new rear main seal, flip the timing chain cover over, apply some oil to the mating surfaces of the cover and seal and then carefully pound the seal into the cover using a hammer and a wide board, as shown in the picture below. Move the board around the perimeter of the seal while pounding to make sure that the seal goes in straight. The seal is installed fully when the outer edge of the seal lines up with the outer edge of the cover (at this point the board will no longer pound the seal in any further, so it's pretty much idiot-proof).

47. The picture below shows the new seal installed in the lower timing chain cover. Also shown is a plastic insert (yellow arrow) that is provided with the seal to make the installation of the seal around the crankshaft flange easier when installing the lower timing chain cover. (We tried to use this piece when installing the cover, but it actually got in the way and kept popping out of the seal prematurely. We eventually gave up and just installed the lower cover without it without any problems.)

48. Before permanently installing the upper tensioner bolt, it is a good idea to bleed the air from it and fill it up with oil. Fill a coffee can or other container with about 4 inches of motor oil, as shown in the picture below. Place the tensioner bolt in the can with the plunger end down and the head end up (so that the feed hole is at the highest point). While submerged, press down on the bolt in the can to compress the plunger fully. This will force any air out of the tensioner. Release the tensioner while submerged to fill the tensioner with oil. Repeat this a few times until you're confident there is no more air in the tensioner. Leave the tensioner bolt in the oil until it's ready to be installed.

NOTE: The above procedure is for the newer style tensioner only. To bleed the older style tensioner, insert a thing wire into the bleed hole in the end of the plunger to activate the check valve inside and then press down on the plunger to compress it fully. Some people like to extend the tensioner slightly so that there is some tension on the upper chain when the engine is started the first time. If you want to do this, submerge the tensioner in oil and pull out on the plunger. Doing so with the tensioner submerged will ensure that oil and not air fills the tensioner. Make sure you do not extend the tensioner too far or too much tension may be applied to the upper tensioner rail, causing premature wear. Use a iterative trial and error process to find the appropriate plunger length.

49. Apply RTV sealant to the mating surfaces of the timing chain covers. These surface are what contact the red shaded areas in the picture below (don't forget about on top of the oil pan and on both the top and bottom of the headgasket. Use ultra-grey import RTV to seal the timing chain covers since it is O2 sensor-safe. Make sure that the oil feed hole for the upper tensioner bolt (yellow arrow in picture below) will not be clogged with RTV when the upper cover is installed.

50. Install the lower timing chain cover first. Apply some oil to the edges of the crankshaft flange and to the inner mating surface of the rear main seal. Carefully position the lower cover, using the guide pins to line it up correctly. As you slide the cover into place, make sure that the rear main seal is sliding onto the crankshaft flange correctly. There is a spring on the engine side of the seal that surrounds the ID and compresses the seal against the crankshaft flange. You want to make sure that this spring remains in place as you slide the seal around the flange (the plastic insert in the third picture above is supposed to assist with this, but it's not necessary to use it - some people also like to drop the oil pan to visually inspect that the spring remained in place during installation, but that is also not necessary). Go slowly and make sure it's done correctly ... the first time. Also, as you slide the lower cover into place, lift up on the headgasket in order to keep it from scraping all of the RTV off of the top edge of the cover. After the lower cover is in place and you're confident that the rear main seal is seated correctly and the RTV seal is sufficient, install the nineteen (19) bolts that secure the cover to the block and oil pan and torque them to 89 in-lbs (10 N-m). NOTE: Make sure to tighten the three (3) lower cover-to-oil pan bolts (red arrows in Step 15) before tightening the sixteen (16) lower cover-to-block bolts or the seal between the lower cover and oil pan may leak.

51. Next install the upper timing chain cover. Again be careful to avoid the headgasket scraping the RTV off of the bottom edge of the cover. It may somewhat difficult to install the upper cover due to engine brackets and the thermostat housing being in the way. I actually recommend that you practice maneuvering the upper cover into position BEFORE applying any RTV. This way you won't get RTV all over everything while trying to figure out how to get the upper cover in place. Once the cover is in place and you're confident that the RTV seal is sufficient, install the ten (10) bolts that secure the cover to the head and the lower timing chain cover. Torque the eight (8) 5mm hex bolts to 89 in-lbs (10 N-m) and the two (2) 6mm hex bolts to 18 ft-lbs (25 N-m). NOTE: Make sure to tighten the two (2) upper cover-to-lower cover bolts (red arrows in Step 12) before tightening the eight (8) upper cover-to-head bolts or the seal between the upper and lower covers may leak.

52. Remove the upper tensioner bolt from the container of oil, wipe it off and then install it in the rear edge of the upper timing chain cover. Torque to the bolt to 22 ft-lbs (30 N-m). (Note: The MKIV Bentley gives conflicting values for the tensioner bolt torque. In multiple places it lists it as 22 ft-lbs (30 N-m), but in one place it lists it at 30 ft-lbs (40 N-m). I'm not sure which one is actually correct, but either one would probably be OK. I torqued mine to 22 ft-lbs and have not had any problems.)

53. Remove the cam locking tool (or plate(s)) from the grooves in the end of the camshafts.

54. Reinstall spark plugs and torque to 18 ft-lbs (25 N-m).

55. Reinstall valve cover (make sure the valve cover seal fits correctly) and torque the ten (10) captured bolt or nuts to 89 in-lbs (10 N-m).

56. On a MKIV, reattach the fuel lines and rear knock sensor wire to the top of the valve cover.

57. That's it!

* 8/2/04 - IMPORTANT INFO FOR THOSE REINSTALLING AN UPPER TIMING CHAIN AFTER A HEAD REBUILD OR HEADGASKET REPLACEMENT

The following information is critical for timing the engine correctly when the upper chain has been removed and the lower timing chain, timing chain cover and tranny have not been touched. There has been some confusion recently during the reinstallation of heads and upper timing chains, and I hope this clears it up for everyone. NOTE: This section does not apply is you are retiming the engine after replacing and/or reinstalling both timing chains, as described in the main part of the DIY above.

If possible, before removing the upper timing chain so you can remove the head, set the crank to Cyl. #1 TDC and don't rotate the engine until the head and upper timing chain have been reinstalled. If this is your situation, then the following information does not apply to you. Since this situation is not always possible (either the crank was not set to TDC before the upper chain was removed or the crank was turned with the upper timing chain disconnected),before reinstalling the head and upper timing chain, you MUST make sure to rotate the crank until Cyl. #1 is at TDC AND and you can see the notch in the intermediate sprocket, as shown by the red arrow in the picture below.

If you do not do this, there is a strong possibility that when the upper timing chain is reinstalled, it will be one half of a tooth off relative to the lower timing chain. To make sure that this situation does not arise, turn the crankshaft until Cyl. #1 is at TDC and then check for the notch in the intermediate shaft. If it is not visible, turn the crankshaft another revolution and check again for the notch. Repeat the process until the crankshaft is at TDC AND you can see the notch in the intermediate sprocket. You may have to rotate as much as 3+ revolutions (4 would get you back to your starting place) in order for both to occur simultaneously. The amount of crankshaft revolution necessary will depend on how far off the crankshaft was from TDC or how much the crankshaft was rotated with the upper timing chain disconnected.

The reason that the above procedure is necessary is due to the fact that the 4 timing sprockets (crank, inner intermediate, outer intermediate and camshaft (2)) do not have the same number of teeth. As a result, a full rotation of the crank sprocket does not produce one full rotation in the other sprockets. The impact of this is that setting the crankshaft to Cyl. #1 TDC does not always simultaneously set the intermediate sprocket to the correct position for the reinstallation of the upper timing chain. If you want to read a more detailed explanation of why this is a problem, check out the following thread - http://forums.vwvortex.com/zerothread?id=1406495. Here are some posts of mine from that thread for the curious, but lazy ...

"Setting the intermediate shaft to the correct position is a critical part of the timing process and is something that not everyone who tries to do the job realizes. The position of the intermediate shaft is critical since it has two sprockets on it with a different number of teeth. If the inner intermediate sprocket is off by one tooth (relative to the crankshaft), then the outer intermediate shaft is off by a fraction of a tooth. This fraction is what messes up the relationship between the intermediate shaft and the camshafts. If both sprockets on the intermediate shaft had the same number of teeth, then it's position in the timing process wouldn't matter. Unfortunately, in order to have the 2:1 crankshaft-to-camshaft rotation ratio and to have sprockets of reasonable diameters, the VW engineers had to make the two intermediate sprockets different sizes."

_____

"Since the crankshaft has 24 teeth, rotating the crankshaft 360° will cause 24 teeth on the inner intermediate sprocket to rotate 24 teeth. The inner inter. sprocket has 32 teeth, therefore, the inner intermediate sprocket will rotate 3/4 of a turn or 270°. If the inner inter. sprocket rotates 270°, then the outer inter. sprocket must also rotate 270°. The outer inter. sprocket has 18 teeth, 270° (or 3/4 of a turn) of which is 13.5 teeth. If the outer inter. sprocket rotates 13.5 teeth, then the camshafts will rotate 13.5 teeth. This make sense since the camshafts have 27 teeth and two rotations of the crank (720°) will cause the cams to rotate one full rotation, or 27 teeth.

Notice that the camshafts do not rotate by an integer number of teeth when the crankshaft is rotated 360°. Instead, it rotated by something plus 1/2 of a tooth."

_____

"Timing the engine starting with both chains off is actually much easier to do (and to understand) than what blownmk2vr6 is trying to do (installing the upper chain after taking the head off). When the chains are off, all you have to do is line up the three marks separately and then put the chains on. If one of the chains is on (most likely the bottom chain), then you also need to understand the relationship between the sizes of the different sprockets. Since they all have a different number of teeth, one full rotation of one shaft does not produce one full rotation of another shaft. Take the crankshaft and inner intermediate sprockets for example (this will help explain what happened to blownmk2vr6). The crank sprocket has 24 teeth and the inner inter. sprocket has 32 teeth. Because of the 3:4 ratio in the number of teeth, the crankshaft has to be rotated FOUR times to have both the crankshaft sprocket and inner intermediate shaft sprocket end up in the same configuration as before starting (a full 96 teeth have to pass - 24*4=96 and 32*3=96). If you only rotate the crankshaft one full rotation, the inner intermediate sprocket will be 90° off (cams will be 1/2 tooth off). If you rotate it twice, the inner intermediate sprocket will be 180° off (cams will line up due to both inner and outer intermediate sprockets having an even number of teeth). If you rotate it three times, the inner intermediate sprocket will again be at 90° off, but in the other direction (cams will be 1/2 tooth off). After the fourth rotation of the crankshaft, the intermediate will be at 360° and everything will line up (cams will line up).

A similar relationship exists between the camshaft sprockets and the outer intermediate sprocket. Their ratio is 27:18 or 3:2. Therefore, it requires TWO full rotations of the camshafts to have the camshafts and intermediate shaft end up in the same configuration as before starting (a full 54 teeth have to pass - 27*2=54 and 18*3=54). If you only rotate the camshafts one full rotation, then the outer intermediate sprocket will be 180° off. After the second rotation of the camshafts, the outer intermediate sprocket will be at 360° and everything will line up. This relationship is not as important to understand as the one between the crankshaft and intermediate shaft since it's unlikely that only the upper chain would be on the engine. It's very likely to have only the lower chain attached though since headwork and a headgasket job only requires that the upper chain be removed."

_________________________________________________________________

* 2/17/05 - IMPORTANT INFO FOR REMOVING THE LOWER TIMING CHAIN COVER ON PRE-MKIV VR6s

|

Quote, originally posted by ubercruizinvr6 » |

|

on an A3 VR6, the thermostat cover part of the thermostat housing has to be removed in order to remove the lower timing chain cover. There is a bolt that is around 2.5 to 3" long that must be removed, and theres really no way around it without pulling that t-stat cover. so, may want to have some G11/G12 and water handy if you're about to attempt the job. |

The picture below (courtesy of ubercruizinvr6) shows the location of the bolt that is blocked by part of the T-stat housing on pre-MKIV VR6s. The section of the T-stat housing that must be removed is shown two pictures below.

_________________________________________________________________

* 5/26/05 - IMPORTANT INFO FOR PERFORMING THIS DIY ON OLDER VRs WHICH HAVE EGR SYSTEMS

The following write-up outlines how to deal with the EGR system on older VRs when replacing timing chains. Thanks to A2B4guy (Jeff) for putting this together and sending it to me. It's a great addition to this DIY. Remember though, if you have any questions about it, make sure to IM him and not me. It will only make my head spin.

_______

The manner in which the EGR system impacts a timing chain service procedure is by complicating the removal of the upper intake manifold and valve cover. So early in your repair sequence you will need to deal with the EGR system. It would be a smart idea to inspect the EGR ports and tubing for heavy buildup or clogs and clean as warranted while the system is apart.

First let's take a look at the overall EGR installation on the motor.

The EGR assembly bolts to the driver's rear corner of the valve cover. It has a tube connected to the intake manifold and another tube connected to the exhaust manifold. It also has a vacuum solenoid and some wiring to operate the system.

As you are unbolting the intake manifold, you will have to also disconnect the EGR connection by unthreading the compression nut on the tube coming from the EGR valve. Then as you try to lift the manifold away, you must slide it off of the tube.

To remove the valve cover, you will have to unbolt the EGR assembly from it. It is attached using two 10mm hex head bolts that go through a wiring harness support as well as the EGR bracket. You can see one of the bolts in the pic, the other is behind the vacuum hose.

As you can see, you will need to disconnect the engine wiring in the upper area so that the harness can be folded back to the driver's side out of your way.

There is very little room so you will have to use the open end of your 10mm wrench to back these two bolts out together a little at a time. There are also two bolts holding the valve to the bracket, but they are no piece of cake either and they would open a gas seal at the intake tube. So stick with the two bolts up front.

At this point the system is being held only by the tube that connects the bottom of the valve to the exhaust manifold. If your repair job does not include removing the head or exhaust manifold, then you can leave this tube connected. You may possibly have to loosen one end of it so that it might swing back away from the valve cover a little bit.

The valve cover can be removed now. If you need to actually remove the EGR valve, first disconnect the vacuum hoses and electrical plugs if not already done. Mark the hoses or make notes to help you reconnect them to the right places later. Then remove the exhaust tube.

Here is the back corner of the motor sans EGR.

This is the EGR assembly as I removed it from my car.

With the EGR system disconnected or out of the way, you can swing the engine harness back up behind the motor if that will get it out of your way. Be very careful handling the wiring. Engine heat makes wires brittle and you get insulation cracks like this one.

You will notice that I have covered most of my harness with pieces of nylon split loom. The original friction tape wrapping was crumbling into dust and the wiring was in danger. This should be done to prevent having to buy a new engine harness sometime later. Remember that a used harness is going to be old and dry too!

For reassembly, you will first want to get the valve cover installed and tightened. Then you can bolt the EGR bracket to the VC. Put the two bolts first through the harness guide plate and then the EGR bracket before threading into the VC. It is amazing how tedious this is, trying to get both bolts started without dropping them and then going only a turn or two at a time on each. Eventually you will get them in and tightened. Limit the torque to about 10 lb-ft.

At this point reinstall the exhaust tube if it was removed, or tighten it if loosened. As you begin to install the upper intake, you will have to slide the EGR fitting over the intake tube before engaging the other manifold mounting points. The tube cannot be flexed into place afterward.

This leaves only the electrical plugs and vacuum lines to connect to the EGR. These can be connected along with the other connections in that area at your convenience. Use zip ties to tie the harness to the support bracket as shown in the first several pictures.

The topic of timing chain noise and the fear of chain breakage comes up frequently enough that I thought it would be valuable to post a sound clip of my timing chain noise. The clip starts out with a hold at 1200 RPMs (with a short blip to 1500RPM), then a slow rev up to 2500RPMs and back down to idle, then a quick rev to 1500RPMs and back down to idle and finally, another hold at 1200RPMs. The timing chain noise (i.e., chain slap) is audible in the 1200RPM holds (it's almost rhythmic at times), but disappears as the revs go above that.

FYI, the engine is in a '99.5 Jetta (MKIV) and has 145k miles on it. Everything on the engine is original except for the MAF (replaced 15k miles ago) and intake manifold shifter rod (replaced 10k miles ago). The noise has been present for at least the last 40k miles and doesn't seem to have gotten any worse. The clip was recorded using a Mini DV digital camcorder sitting directly below the tranny bell housing.

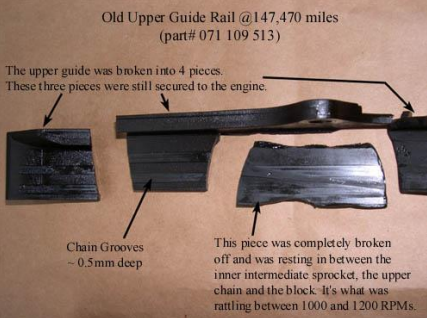

UPDATE (1/5/04) ...................

A bunch of us replaced my timing chains this weekend (1/3/04 and 1/4/04 - 147.5k miles on the original parts) since I couldn't stand the rattling noise anymore and didn't want to risk destroying the engine any more than I already had. Well, we found out what was rattling. The upper guide rail was snapped in half and a 1"x2" piece from the middle of it had slid down and wedged itself between the upper chain, the inner intermediate sprocket and the block. The piece rattled whenever the engine was running at it's harmonic frequency, which appears to be somewhere between 1000 and 1200 RPMs.

I'll post pics as soon as the whole job is complete - we still need to put the tranny back in and reassemble the engine bay.

Based on my noise and what we found, I'm confident when I say that if you hear a rattle then some part of the timing chain setup is either loose or broken. That being said, I wouldn't ignore timing chain noise too long as it means that there is the POTENTIAL for something bad to happen. Not that it definitely will, just that it might. I'm sure I could have driven for quite a while longer with the guide rail chunk rattling behind the intermediate sprocket, but I'm glad that the broken piece is out of there and I know that it can't cause a problem in the future.

I thought I'd post some pics of the timing chain parts I removed in the Timing Chain DIY that I posted.

Aside from the upper guide rail that was snapped in a bunch of pieces and was causing a loud rattling noise between 1000 and 1200 RPMs, the rest of the parts show extremely little wear considering they had been in use for almost 150k miles.

It looks like the newer style upper timing chain parts actually do wear significantly better than the older style parts. Now if only VW could manufacturer an upper guide rail that didn't fail so frequently ...

Here are the pics. Enjoy.

Gary

Edit: Before someone asks, oil changes were done every 10k miles using dino oil up to 100k and synthetic (Mobil 1) from then on.

Most Popular

-

1

-

2

-

3

-

4

-

5